Dedicated in May, 2017, the Daikin Texas Technology Park (DTTP) located in Waller, Tex. outside of Houston, is a 4.2 million sq. ft. manufacturing marvel that incorporates state-of-the-art HVAC production technology.

Of that 4.2 million sq ft., 1.9 million is devoted to manufacturing and 1.9 million sq. ft. for the distribution center. Another 400,000 sq.ft. is for marketing and customer support, training, and cafeteria spaces.

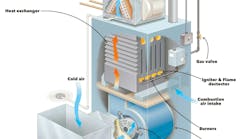

The new factory showcases a state-of-the-art production technology system that utilizes a modular production line that responds to fluctuations in production amount and automatically controls production progress by taking ad-vantage of Internet of Things technology.

“We have 19 psychrometric labs, for testing mini-splits, PTACs, and all residential and commercial products,” said James Gilbert, product manager, and our guide during an extensive tour of the facility.

Want some exercise? Just take a walk around this property: it has a circumference of two miles, and is two-thirds of mile in length. It houses 315 shipping-and-receiving docks, for accepting raw materials and shipping product to 220 company-owned distribution outlets, and over 1,000 independent and company-operated distribution locations.

The DTTP facility has been a blessing to the local economy. It currently employs approximately 6,500, and that number continues to climb. During our visit, orientation was underway for the most recent new-hires, and others were in training.

The technology used here includes robotic carts that deliver materials to assembly lines, a unique “smart pallet” manufacturing process, and thorough

run-testing of each unit prior to shipment.

“Assembly training is provided in ‘Dojos,’ added Gilbert,“ and is a two-step process. “Assembly training involves learning the assembly process, and then, the pacing required to meet daily line production speed, in order to meet production goals,” he said.

“And we give people chance to find their right place in the production team,” Gilbert continued. “If somebody is struggling with a particular line process, we’ll find another place for them where they’re more comfortable,” he said.

Worker safety and emergency preparation at the DTTP is of paramount importance.

“We are blessed to have a medical facility on-site, operated by a local network of doctors and from the Memorial Hermann Group. Any time someone is working in this building, a Physician’s Assistant is on call in the medical facility,” Gilbert said.